AERIS

Modular Window Air Conditioner for Small Living Spaces

Project Type: Research-driven industrial design

Focus Areas: Mechanical system understanding · User safety · Environmental efficiency · Educational value

Applied research exploration focused on safety, modularity, and maintenance accessibility in residential HVAC systems for small living environments.

01

Intro

Key Insights

Assembling Hardness

The excessive weight of conventional window air conditioners introduces multiple layers of risk throughout the product’s lifecycle.

From initial installation to long-term maintenance, weight transforms a basic household appliance into a physically demanding and unsafe object.

Load on Window

Maintenance Barrier

“Research Evidence — Why Window AC Installation Is Unsafe”

02

Research

ACs are too heavy for one person

↓

Poor installs cause falls & injuries

↓

Comfort shouldn’t come with strain

↓

Make cooling safe, light & effortless

Failure Scenario: Single-Person AC Removal Injury

Seasonal removal of window air conditioners is commonly performed by users without professional assistance.

In many residential and rental settings, the task is completed by a single occupant due to limited access to help.

Incident Description

During the removal of a conventional window air conditioner, a working adult attempted to disengage and lift the unit alone.

The product’s monolithic structure required lifting the full system weight while maintaining balance at the window edge.

As the unit was partially released from the frame, its concentrated outward mass exceeded the user’s stable lifting capacity.

A sudden load shift occurred, forcing the user to compensate mid-lift to prevent the unit from dropping. This resulted in acute lower-back strain.

The injury prevented the user from performing work duties for approximately one week.

Root Cause Analysis

1. Concentrated system weight

2. Lack of modular separation

3. No staged removal or intermediate load support

03

Observed Cases

Heavyweight in Common

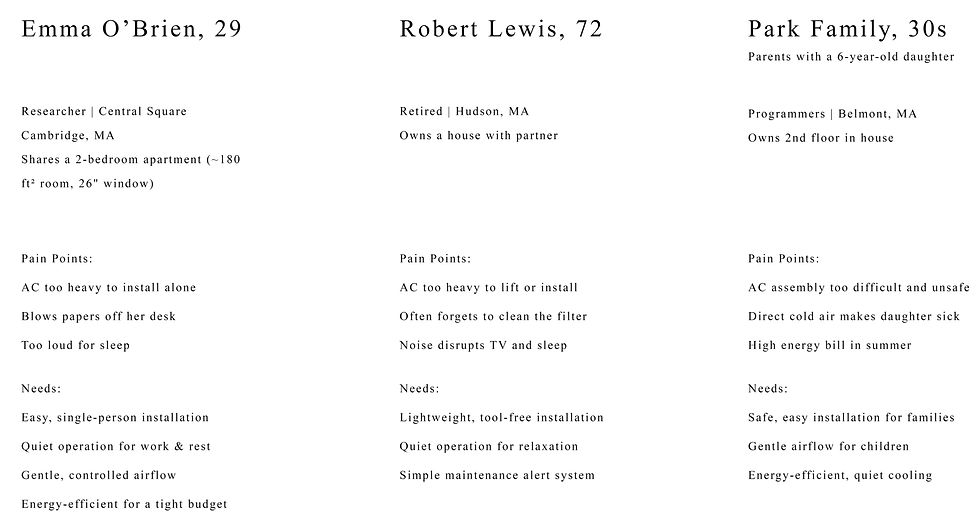

Emma

Robert

Park

Who Is This AC System For?

This research focuses on safer HVAC system architectures in institutional environments where window-mounted air conditioning units are often installed, maintained, or replaced by staff or residents under significant safety and operational constraints.

Primary Usable Environments

University & College Housing

Dormitories, graduate housing, faculty apartments

Assisted & Senior Living Facilities

Residences with higher ergonomic risks and reduced lifting capacity

Public & Subsidized Housing Programs

Supportive housing requiring durable and maintainable infrastructure

Why Places Care?

Institutional housing facilities frequently rely on window-mounted air conditioning systems due to infrastructure constraints. Installation and maintenance cycles often involve non-specialist staff and result in recurring risks of injury liability, labor strain, and operational cost. This research explores modular system architecture and interior-only installation design as potential interventions to reduce these risks at scale.

Applied Research Value

This project is not a commercial product proposal, but functions as an applied research exploration into HVAC system design that prioritizes safety, modularity, and serviceability in institutional contexts that will change people's lives.

LBs

Survey data and consumer reports indicate that over 60% of window AC users experience difficulty lifting their unit, commonly reporting back strain, shoulder pain, and fatigue.

30 LBs

Ideal Weight

Target Area

80 LBs

04

Probelm Addressing

5-gallon water

Average AC

70 LBs

fully packed suitcase

40 LBs

small dorm frige

50 LBs

wooden table

60 LBs

05

Root Cause

Why Window AC Units Are Heavy?

Heat exchangers

Compressor (primary mass)

Fan System

1. Traditional ACs are designed as sealed systems

2. Assembly is optimized for factory efficiency, not user handling

3. Structural rigidity is prioritized over modular access

Weight is not excessive because of performance requirements, but because the system is designed as a single, inseparable mass.

Design Strategy: Modular Weight Distribution

Traditional AC

Single Mass

1

2

3

Separate mass into functional modules

High-weight components should be divided into smaller, independently handled units rather than fused into a single structure.

Enable staged installation

Installation should allow components to be placed sequentially,

reducing peak lifting load and improving user control during setup and removal.

Maintain structural stability

At no point should the system rely on unstable balance or unsupported weight at the window edge.

Separate high-mass Components

Stage module placement

Secure to stable structural reference

06

Ideation

What if…

Your AC Could Install Like a Bookshelf?

Most household furniture can be installed by a single user through staged assembly and stable placement.

Window air conditioners, by contrast, require full-system lifting during installation.

This project explores how AC installation can adopt furniture-like assembly logic by reducing single-lift load and enabling modular placement.

Interior Constructional Design

AC Frame Design

Rear Exhaust layout

Complete screen coverage

These sketches explore early system logic and spatial configuration.

Interface and surface details are preliminary and do not represent final design decisions.

Compressor Unit

Condenser Coil Block

Aeris Modular System

Each module of Aeris functions independently; compressor, airflow, and sensor units operate through smart synchronization, simplifying maintenance while enabling precise adaptive cooling

07

Modular System

Axial-Centrifugal Motor Unit

Dual-Fan Turbine Assembly

Digital Thermal Sensor Port

Humidity Sensor

8 lBs

3 lBs

15 lBs

4 lBs

3 lBs

3 lBs

4 lBs

2 lBs

Average Window AC

65 lB

42 lB

total system weight

no single lift exceeds target handling range

Peak single-lift load reduced compared to conventional AC

Distributed Assembly Approach

AERIS is designed to be installed by a single user through a staged process

that prevents unstable lifting and distributes weight across multiple secure steps.

1. Install Structural Frame

The structural frame is installed independently to establish a secure reference before any high-mass components are introduced.

08

Modular System Architecture

Magnetic Connection

Sliding Mechanism

2. Insertion of Module

Structural frame interface

Load-bearing rail

3. Locking & Load Securing

Once seated, the module automatically locks to the structural frame, allowing hands-free installation.

Manual-locking rail interface

The locking interface transfers vertical load directly to the frame, eliminating sustained user support.

4. Modular Service & Component Replacement

AERIS is not a sealed appliance but a serviceable system.

Once installed, individual modules can be removed or replaced independently without tools, simplifying maintenance and extending product lifespan.

System Deployment

Clear System Boundaries

Core functional zones are spatially separated, allowing the system to evolve without redefining its architecture.

Unlike traditional window air conditioners that rely on external brackets and two-person installation, Aeris exists as part of the interior architecture.

The modular system enables installation, removal, and servicing to occur entirely from the interior side, reducing risk while maintaining a consistent spatial presence within the living environment.

Interior-only installation

Integrated into window architecture

Modularity for Adaptability

Modular components enable focused upgrades or replacements without affecting the entire system.

Separation of Concerns

Each component can be removed or updated without compromising system integrity.

Legible Interface Design

Like a car dashboard, Aeris stays calm and clear signals appears when something needs attention. Each icon lights up only for real issues

-

Leak Alert

-

Condensation Drain Alert

-

Compressor Issue

-

Clean Filter

-

Airflow System

-

Air Quality

Material Strategy

Alluminum Alloy

Tempered Glass

Low-Voc Coatings

100%

_gif.gif)

_gif.gif)

100%

100%

_gif.gif)

Why it Matters?

Most window ACs end up in landfills within 5 years due to corrosion, noise, or part failure.

Aeris reimagines the cycle: designed for part replacement, recycling, and reuse

09

System-Level Implications & Longevity

The design emphasizes system resilience through clear structure and replaceable components, enabling continued use without full replacement.

Longevity is treated as an outcome of organization, not optimization.

System Architecture

Internal System Zoning

Core functional systems are spatially separated, reducing interdependence and preventing single-point failure from cascading across the system.

Forgiving Architecture

The system is designed to tolerate partial failure, prioritizing continued operation and ease of intervention over total replacement.

Material choices support system clarity

10

11

Further Development

Optional remote access allows basic system monitoring and adjustment from a mobile device,

supporting flexibility without changing the primary interaction model.

System-Level Implications & Longevity

This project is framed as an applied research exploration into how HVAC system architecture can influence safety and long-term serviceability within institutional housing environments.

Rather than proposing a finalized product, the work uses a window-mounted air conditioning system as a case study to examine design decisions related to installation risk and maintenance access.

In institutional contexts such as university housing, assisted living facilities, and public housing, HVAC equipment is frequently installed or serviced by non-specialist personnel under safety and labor constraints. This research investigates modular system logic as a potential strategy for reducing physical handling risk while improving operational feasibility at scale.

The architectural principles explored in this project, modular weight distribution and interior-only service access, are intended to inform broader applied research in facilities management, building science, and safety-oriented design.

The project is positioned to support continued institutional investigation rather than immediate commercial deployment.

Concept-Level Ergonomic Exploration

A full-scale physical mock-up was constructed using a foam-core internal structure and plywood exterior shell to explore the feasibility of modular installation and handling workflows. The mock-up was not intended as a functional prototype, but as a physical reasoning tool to evaluate scale, weight perception, and installation sequencing.

Exploratory handling exercises suggest that separating the system into smaller modules significantly reduced perceived lifting difficulty compared to a single monolithic unit. Individual components were handled comfortably by a single person, supporting the assumption that staged installation could lower peak physical strain during setup and removal.

The assembly process was explored through a sequence of shorter handling steps rather than a single heavy lift. This physical walkthrough informed the proposed installation logic and highlighted potential advantages in reducing strain risk and improving controllability during interior-only installation. These observations are qualitative and intended to inform future ergonomic testing within institutional research or facilities management contexts.

Concept-level ergonomic test — users lifted full-scale modular mock-up (foam core + wood shell).

Perceived lift: “easy” (< 8 lb equivalent).

Assembly: 3–4 shorter steps instead of one heavy lift → strain risk ↓ 60 %, time ↓ 20 %